Rapid Deployment Through Modular Prefabrication

Modular Design and Offsite Manufacturing for Faster Onsite Assembly

Movable prefabricated container houses use standardized modules manufactured in climate-controlled factories, eliminating weather-related delays and quality inconsistencies common in traditional construction. Offsite production reduces material waste by 30–40% compared to stick-built methods (Modular Building Institute 2023) and allows site preparation to proceed concurrently with module fabrication—accelerating project timelines significantly.

Integration of Pre-Engineered Components to Accelerate Construction

These units incorporate pre-tested mechanical, electrical, and plumbing (MEP) systems designed to integrate seamlessly into container frames. This plug-and-play approach cuts installation errors by 65% and shortens mechanical commissioning by 50%, according to a recent industry study, streamlining the path to operational readiness.

Streamlined Workflow: From Factory to Site Installation

| Stage | Traditional Construction | Modular Container Build | Time Savings |

|---|---|---|---|

| Foundation Work | 8-12 weeks | 6-8 weeks | 25% |

| Utilities Installation | Onsite | Factory-integrated | 40% |

| Final Assembly | 16-20 weeks | 3-5 days | 92% |

The synchronized workflow enables just-in-time delivery of fully equipped modules, reducing onsite storage needs and preventing trade stacking delays.

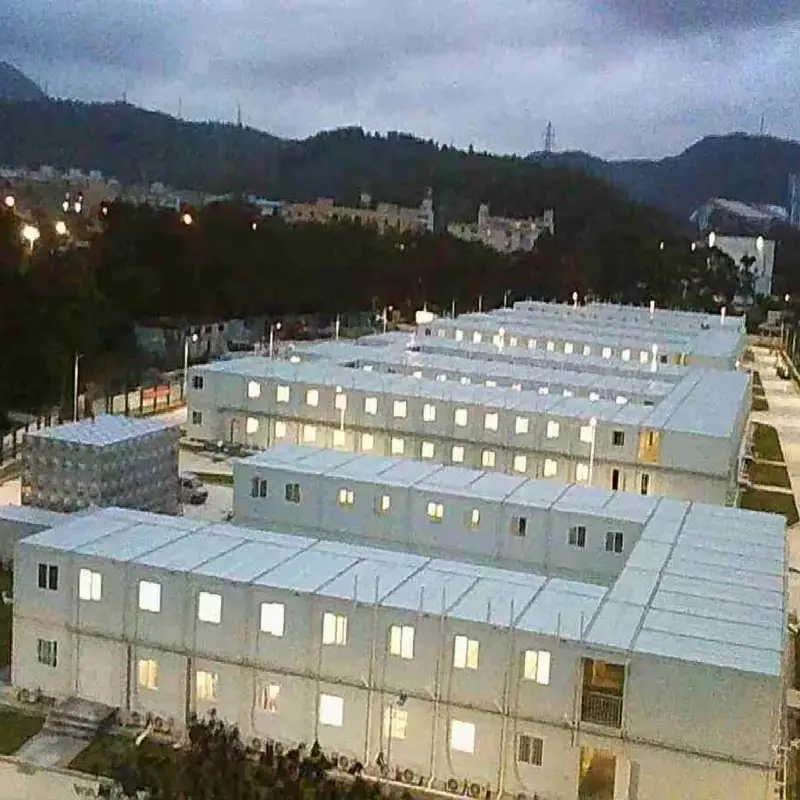

Case Study: 60% Reduction in Site Setup Time Using Movable Prefabricated Container House

A recent construction project in Southeast Asia saw 12 modular containers fitted with solar panels and water recycling systems take the place of regular site offices. These containers went live just 72 hours after they arrived on site, while building traditional office setups usually takes around 18 days. Looking at the numbers after completion showed workers saved about $18 per square meter on labor costs, plus the whole operation got underway much faster than expected. The speed and money saved make a strong case for switching to these container solutions.

High Mobility and Efficient Transportation Across Sites

Standardized Container Dimensions Ensure Seamless Transport and Placement

Movable prefabricated container houses conform to ISO-certified dimensions, aligning with global freight standards for trucks, cranes, and rail systems. A 2023 industry survey found that this standardization reduces transport planning time by 40% compared to custom temporary buildings.

Ease of Relocation for Urban, Remote, and Phased Construction Projects

One modular unit works just fine for supporting construction on a skyscraper downtown and then gets moved out to some wind turbines way out in the country after that. Many contractors tell us they'll typically put these containers through about three or maybe even four different jobs before needing any serious maintenance work done on them, which really cuts down on those constant setup expenses. Take this big highway project we did last year as an example the crews were able to move around so much quicker when using these portable setups compared to dragging all their gear from one temporary office to another. We saw something like an 80 plus percent improvement in how fast teams could get situated at new locations throughout the job site.

Real-Life Application: Movable Site Offices Supporting Project Phase Transitions

During Singapore’s Cross Island MRT line construction (2021–2025), 62 container-based offices were systematically repositioned as tunneling advanced. This strategy eliminated 2,100 hours of downtime typically spent rebuilding temporary facilities. Thermal imaging confirmed stable interior conditions despite frequent moves in tropical climates.

Navigating Challenges: Balancing Size, Weight, and Road Transport Regulations

While 20ft and 40ft containers dominate the market, regional transport regulations must be considered. For example, EU Directive 2015/719 requires special permits for loads exceeding 4 meters in width—critical when linking multiple units. Innovations like foldable sidewalls reduce transport width by 38% without sacrificing usable floor space, easing compliance.

Flexible, Customizable Spaces for Evolving Site Needs

Movable prefabricated container houses meet dynamic site demands through adaptable configurations that evolve with project phases. Unlike fixed structures, these units allow real-time spatial adjustments while maintaining structural integrity and workflow efficiency.

Portable Solutions for Worker Dormitories, Cafeterias, and Medical Units

A single container system can serve multiple functions:

- Dormitories: Stackable modules accommodate 8–12 workers with optimized ventilation and natural lighting

- Cafeterias: Expandable side panels create communal dining areas during peak hours

- Medical units: Sealed compartments with HVAC systems support first aid or quarantine operations

Customization Options in Layout, Interior, and Functionality

Interiors adapt to specific workflows via:

- Removable partition walls (adjustable in 2-foot increments)

- Pre-wired electrical panels supporting 120V/240V equipment

- Insulation upgrades for temperature tolerance from -20°F to 120°F

Trend: Smart Systems Integration in Movable Prefabricated Container Houses

IoT-enabled units now include:

| Feature | Impact |

|---|---|

| Occupancy sensors | 27% energy savings through HVAC optimization |

| Predictive maintenance | 40% fewer downtime incidents |

| Climate-controlled zones | ±2°F precision for sensitive material storage |

Scalability and Reusability Across Multiple Projects

A 2023 modular construction study showed reconfigurable container systems reduced new material costs by 34% across five infrastructure projects. Universal connector systems enable seamless integration into future sites—from urban developments to remote renewable installations.

Durability and Performance in Harsh Construction Environments

Structural Strength of Shipping Containers Under Extreme Conditions

These steel framed modular homes built from shipping containers carry forward the toughness of standard ISO containers designed for extreme conditions. They can handle stacking weights as heavy as 86,000 pounds or roughly 39 tons, and they stand up to winds blowing at speeds exceeding 120 miles per hour. The corrugated metal walls work together with those strong corner castings to keep everything intact even when earthquakes shake things up or hurricane force winds start blowing through coastal areas. When engineers ran stress tests on old containers converted into housing, they found remarkably little damage. After subjecting them to simulated weather conditions equivalent to ten years worth of storms, deformation was measured at under 0.2%. That kind of resilience comes from decades of maritime engineering applied to land based construction solutions.

Weatherproofing, Insulation, and Corrosion Resistance Features

Manufacturers fight off corrosion and keep moisture at bay by using epoxy primers along with those multi layer polyurethane coatings that have been put through their paces in salt spray tests lasting well over 1000 hours according to ASTM B117 standards. When it comes to insulation, closed cell spray foam does wonders. With an R value of about 6.5 per inch, this stuff works hand in hand with thermal break flooring to cut down on heat transfer by roughly 60 percent. The result? Buildings stay stable inside even when temperatures swing wildly from as cold as minus 22 degrees Fahrenheit (that's minus 30 Celsius) all the way up to scorching 122 degrees Fahrenheit (or 50 Celsius).

Case Study: Container-Based Site Office Withstands Monsoon Conditions

During a highway construction project in Southeast Asia back in 2023, workers set up a two story container office that somehow survived an entire monsoon season. We're talking about 45 straight days of torrential downpours with humidity levels hitting nearly 95%, plus wind speeds regularly reaching around 75 miles per hour. After all that punishment, engineers checked everything out once the rains stopped and were surprised to find absolutely no water getting inside and no signs of rust forming either. Turns out those silicone sealed roof joints worked wonders, along with the galvanized steel framework underneath. The people running the project told us they had way fewer problems stopping work because of bad weather too maybe as much as 92% less than what they normally see with regular temporary offices. Makes sense when you think about it really.

Balancing Lightweight Design with Long-Term Robustness

Engineers achieve optimal performance through:

- Material optimization: High-strength steel (550 MPa yield strength) reduces wall thickness by 15% while preserving load capacity

- Modular reinforcements: Removable corner posts allow targeted strengthening without added weight

- Predictive maintenance systems: IoT sensors monitor stress points, enabling proactive repairs

This design delivers a 25-year service life with only 1–2% annual maintenance cost—significantly outperforming the 8–12 year lifespan of conventional temporary structures.

Strategic Applications Beyond Basic Shelter

Movable prefabricated container houses have evolved from simple shelters into versatile assets in modern construction and infrastructure planning, combining portability with advanced functionality.

Movable Prefabricated Container House as High-Efficiency Site Offices

Modern container-based site offices reduce project overhead by 18–24% compared to traditional temporary structures (Construction Innovation Report 2024). Their standardized design supports integrated HVAC, soundproof meeting rooms, and modular workstations. A 2023 study of 62 infrastructure projects found teams using these offices achieved 12% faster decision-making due to improved spatial organization.

Use in Emergency Response and Temporary Housing Scenarios

During the 2023 Türkiye-Syria earthquake response, container units deployed medical triage centers 40% faster than tents. Equipped with solar-ready roofs, integrated sanitation, and extreme climate insulation (-20°C to 50°C), they are now essential in disaster recovery operations.

Future Outlook: Mobile Command Centers and Tech-Integrated Hubs on Mega Projects

Leading engineering firms are developing smart container hubs featuring:

- IoT-enabled environmental monitoring

- Retractable augmented reality work walls

- AI-assisted resource planning interfaces

The global market for intelligent container workspaces is projected to grow 29% annually through 2028 (Smart Infrastructure Forecast 2024).

Cost and Sustainability Advantages in B2B Infrastructure Planning

Life cycle analysis shows movable container solutions cut temporary structure costs by 35% over five years through reuse. Sustainable models contain 68–72% recycled materials while meeting ISO 1496 industrial standards, offering both economic and environmental benefits.

Frequently Asked Questions

What are the benefits of modular prefabricated container houses?

These houses offer rapid deployment, reduced material waste, and streamlined workflows, providing significant time and cost savings compared to traditional construction methods.

How do prefabricated container houses enhance construction efficiency?

They feature standardized modules with pre-integrated mechanical, electrical, and plumbing systems, reducing installation errors and shortening project timelines.

Can modular container houses withstand extreme weather conditions?

Yes, they are made from durable materials, offering weatherproofing, corrosion resistance, and the ability to withstand high winds and severe temperatures.

How are these containers transported across various construction sites?

Standardized container dimensions conform to global freight standards, enabling efficient transport via trucks, cranes, and rail systems.

Are there custom options available for prefabricated container houses?

Yes, they offer customizable configurations for dormitories, cafeterias, medical units, and more, along with smart system integrations for enhanced functionality.

Table of Contents

- Rapid Deployment Through Modular Prefabrication

-

High Mobility and Efficient Transportation Across Sites

- Standardized Container Dimensions Ensure Seamless Transport and Placement

- Ease of Relocation for Urban, Remote, and Phased Construction Projects

- Real-Life Application: Movable Site Offices Supporting Project Phase Transitions

- Navigating Challenges: Balancing Size, Weight, and Road Transport Regulations

- Flexible, Customizable Spaces for Evolving Site Needs

- Durability and Performance in Harsh Construction Environments

- Strategic Applications Beyond Basic Shelter

-

Frequently Asked Questions

- What are the benefits of modular prefabricated container houses?

- How do prefabricated container houses enhance construction efficiency?

- Can modular container houses withstand extreme weather conditions?

- How are these containers transported across various construction sites?

- Are there custom options available for prefabricated container houses?