Optimizing Logistics and Reducing Shipping Costs with Bulk Pack Container Housing

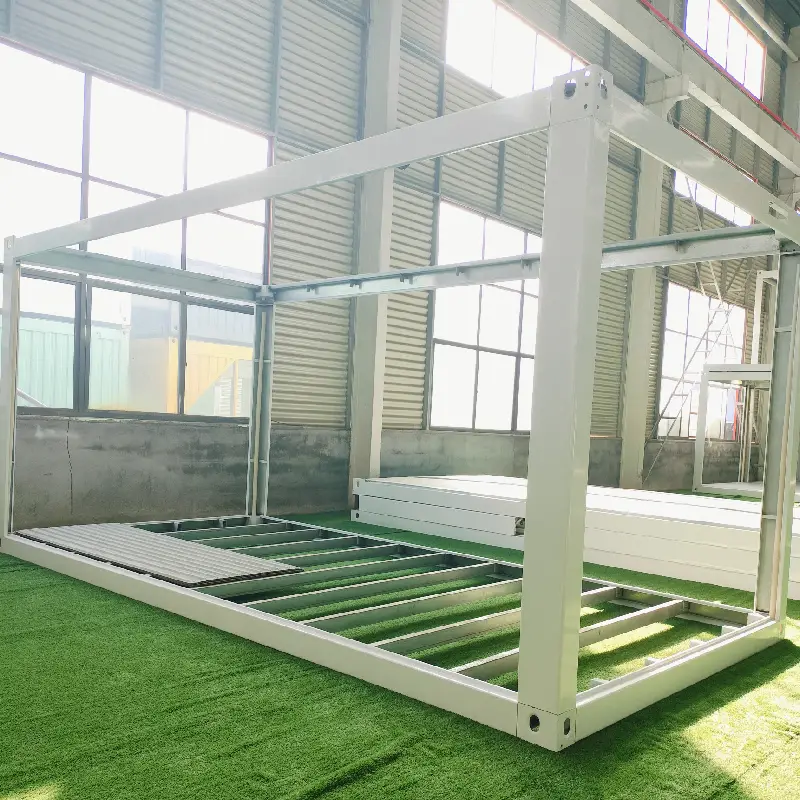

Bulk pack container housing transforms shipping economics through modular design that maximizes spatial efficiency during transit. These standardized units enable dense stacking configurations, optimizing trailer and container space and reducing the number of shipments required for large-scale projects.

Modular Design Enables Efficient Space Utilization in Transit

Bulk pack containers are designed with precise geometry that lets them lock together and stack uniformly, which cuts down on all that wasted air space we see so much in regular shipping methods. According to recent logistics data from 2023, this modular system can boost payload density by around 40% when compared to old school packaging solutions. What makes these containers really stand out is their standardized size. They fit right into the worldwide shipping network whether its moving goods via rail or across oceans by ship. Because everything fits together so well, there's no need to repackage items or deal with those annoying delays during transfers between different transportation methods.

Case Study: Automotive Industry Cuts Shipping Costs by 30%

One major car maker recently switched to bulk container storage for moving engine parts throughout their North American operations. When they swapped out all those custom wooden crates for standard containers, shipping expenses dropped around 30 cents per unit while loading dock workers saved nearly 40 minutes each time they loaded trucks. The change basically wiped out almost all the wood waste that used to pile up from discarded crates, which is why many factories are now looking at these bulk container solutions not just for saving money but also cutting down on landfill trash.

Consolidation Strategies That Reduce Average Shipping Costs by 20–35%

Strategic consolidation using bulk pack container housing allows companies to combine shipments into optimized loads, lowering per-unit transportation costs by 20–35%. These savings result from reduced fuel consumption, fewer handling requirements, and improved route planning—all enabled by standardized container dimensions that integrate seamlessly with modern logistics systems.

Maximizing Space Efficiency and Reusability Across the Supply Chain

Stackable and Collapsible Designs That Cut Empty Freight Miles by Up to 60%

Stackable and collapsible designs for bulk pack containers cut down on empty freight miles by around 60 percent according to recent studies. When containers can nest together or fold flat, companies manage to fit far more units onto each transport vehicle. This makes a big difference for logistics teams trying to plan loads efficiently while cutting back on those frustrating half-empty return trips that waste fuel and time. The push toward standardized dimensions has really helped here too. With uniform sizes, warehouses and shipping departments get better at maximizing every inch of truck space. The result? Lower transportation expenses overall plus significantly reduced carbon footprints throughout the entire supply chain network.

Reusable Bulk Pack Container Housing Minimizes Material Waste

Reusable bulk containers cut down on waste compared to those one-time use packages we see everywhere these days. These containers are built tough enough to handle being moved around dozens of times without falling apart, so companies don't have to keep buying new ones all the time. The sturdy build keeps products safe during shipping too. What starts as just another cost becomes something that pays off over years instead of months. Many manufacturers switch to these durable options because they save money in the long run while also helping reduce landfill trash from all those discarded boxes and plastic wraps.

Designing for Circular Supply Chains to Improve Return Efficiency

The bulk pack container system really helps support circular supply chains because of their standard sizes and built-in tracking features that make everything easier to manage. These containers are made so they can be cleaned out quickly after use, maintained without much hassle, and rearranged as needed for different purposes. They basically cut down on the headaches of getting stuff back into circulation and let businesses reuse them time and again in all sorts of ways. When companies adopt this kind of closed loop thinking, returns get processed faster, less material gets wasted overall, and it just makes sense from both an environmental standpoint and meeting those ever-changing regulatory requirements most corporations have to deal with nowadays.

Enhancing Product Protection and Reducing Transit Damage

Data Insight: Up to 45% Fewer Damage Claims with Robust Container Housing

According to industry reports, bulk pack containers today lead to around 45% fewer damage claims than traditional packaging methods as noted in the Packaging Performance Report for 2023. These containers are built with solid structural integrity that stands up to stacking pressures, vibrations during transport, and impacts from handling. The protection isn't just an afterthought either it's actually woven right into the design itself. What does this mean practically? Less money lost due to broken or damaged items when they reach their destination. Plus customers get what they paid for intact, which obviously makes them happier with their purchases overall.

Engineering Standards for Durability in Harsh Transport Environments

Bulk pack containers are constructed according to strict specifications that handle harsh environments without breaking down. Before being put into service, these units go through extensive evaluations including checks against drastic temperature changes, exposure to humidity, and physical impacts during transport. The design features strong corner reinforcements, materials that resist damage from collisions, and seals that keep out water and dirt effectively. These containers can stack safely when loaded with weights reaching around 30 thousand pounds, and they function properly even when temperatures drop below freezing or climb well above room temperature, sometimes as high as 160 degrees Fahrenheit. This kind of durability means businesses get dependable storage solutions no matter where their goods need to travel.

Bulk Pack vs. Traditional Wooden Crates: A Comparative Analysis

Bulk pack containers actually last longer and protect goods better than those old wooden crates most folks still use. Wood has real issues absorbing moisture, nails tend to wear out over time, and splinters are just plain annoying plus they can ruin products. The numbers tell the story too bulk packs cut down on damaged goods by about 30 to 45 percent compared to wood, keep things dry around 60% better, and stack much stronger too roughly 40% improvement there. No more worrying about splinters damaging cargo either. These containers perform reliably even after being reused many times, which is why so many companies handling expensive or large volumes of goods have switched over recently.

Standardizing Operations to Improve Labor Efficiency and Scalability

How Standardized Units Reduce Handling Errors and Labor Costs

When companies use standardized bulk pack containers for their housing needs, they tend to see fewer mistakes during handling and save money on labor costs because everyone follows the same workflow across big projects. The fact that all containers have exactly the same size and come with set assembly instructions means workers don't need as much training before starting their jobs, which naturally leads to fewer errors while working. Some studies out there suggest that going standard can actually shorten training periods by around 40 percent and bring down mistake rates somewhere near 30%. These improvements translate into better overall efficiency for operations teams and ultimately help keep those labor bills under control.

Streamlining Warehousing and Last-Mile Deployment Processes

When containers all have the same size, it makes warehouse work much easier and speeds things up for getting products out there at the final stage. The standard sizes mean better fitting on pallets and work well with those machines that handle goods automatically, so we need less space overall and loading goes faster too. This matters a lot when time is critical, like setting up temporary shelters after disasters or building facilities in hard to reach areas. The uniformity just makes everything simpler to manage, and many companies report saving around a quarter of their usual setup time because of it.

Enabling Rapid, Scalable Deployment for Time-Sensitive Large Projects

Bulk pack container housing enables rapid, scalable deployment for large-scale, time-critical projects. Modular systems can be transported and assembled quickly, reducing on-site construction timelines and accelerating project completion.

Fast Setup Solutions for Remote and Emergency Infrastructure Needs

When setting up housing in remote areas or during emergencies where building from scratch just isn't feasible, bulk pack containers offer quick solutions that save time and resources. Most of these modular systems get put together within just a few days, which makes them perfect for situations like after disasters strike, at remote mining operations, or when establishing temporary clinics in underserved regions. What really stands out about these units is how they come with standardized parts that snap together easily. Even if there aren't many trained workers available on location, crews can still assemble everything pretty quickly thanks to this design approach. Many field teams have reported getting entire setups operational within hours once containers arrive at site.

Case Study: Modular Container Housing in Mining Camp Expansion

A mining camp expansion project used prefabricated container modules manufactured off-site while site preparation occurred simultaneously. This parallel workflow reduced the overall project timeline by 40% compared to traditional construction, enabling earlier production start-up without compromising quality.

Off-Site Fabrication Trends That Shorten Project Timelines

When building bulk pack container housing away from job sites in factories instead of on location, things just run smoother overall. The quality stays better because there's no rain messing with materials or wind blowing parts around. Plus workers can actually focus on their tasks without dealing with bad weather conditions holding everything back. Most projects end up cutting down about a third to half of what used to take place right at the construction site itself. There's also noticeably less wasted materials lying around everywhere these days too. And let's face it, nobody wants someone getting hurt while trying to piece together something that was supposed to be ready when it arrived. With proper engineering done ahead of time, most containers just slot into place exactly where they need to go without needing those expensive last minute fixes that always seem to throw schedules off track.

FAQ

What are bulk pack containers?

Bulk pack containers are standardized, modular units designed for efficient stacking and optimal space utilization during shipping and storage.

How do bulk pack containers reduce shipping costs?

These containers maximize spatial efficiency, reduce empty freight miles, and enable strategic consolidation of shipments, resulting in reduced transportation costs.

Why are bulk pack containers considered environmentally friendly?

They are reusable, minimizing material waste, and their design supports circular supply chains, which reduces landfill waste.

Can bulk pack containers withstand harsh transport conditions?

Yes, they are engineered for durability, able to withstand significant temperature variations, impacts, and stacking pressures.

How do bulk pack containers compare to traditional wooden crates?

Bulk pack containers offer better protection, are more durable, reduce damage, and are more space-efficient compared to wooden crates.

Table of Contents

- Optimizing Logistics and Reducing Shipping Costs with Bulk Pack Container Housing

- Maximizing Space Efficiency and Reusability Across the Supply Chain

- Enhancing Product Protection and Reducing Transit Damage

- Standardizing Operations to Improve Labor Efficiency and Scalability

- Enabling Rapid, Scalable Deployment for Time-Sensitive Large Projects

- FAQ